Facilities

See below the faciliites and tools we use for making, measuring, and modelling magnetic materials

Fabrication

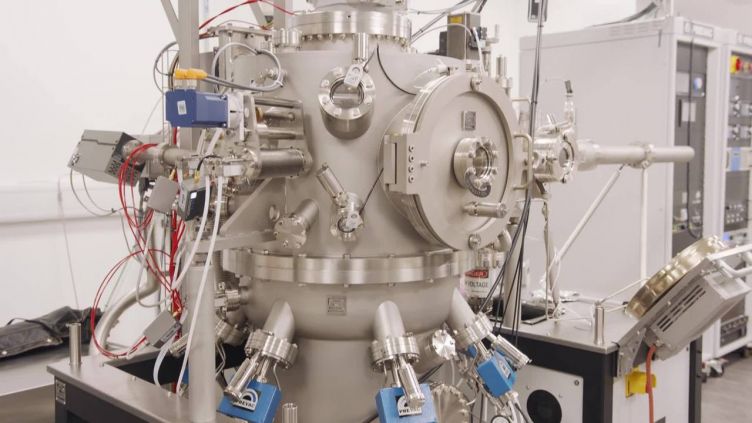

Multi-source thin film deposition system

This PREVAC system allows simultaneous deposition from a large number of sputter and evaporation sources. It also offers the capability to create variable compositions on a single wafer, makes it ideal for materials discovery in such areas as high entropy metal alloys (alloys with five or more elements in similar proportions).

The system allows the exploration of new functional materials systems, for example, thin-film magnetic multi-layers and functional ceramics.

The system is part of the Royce Discovery Centre.

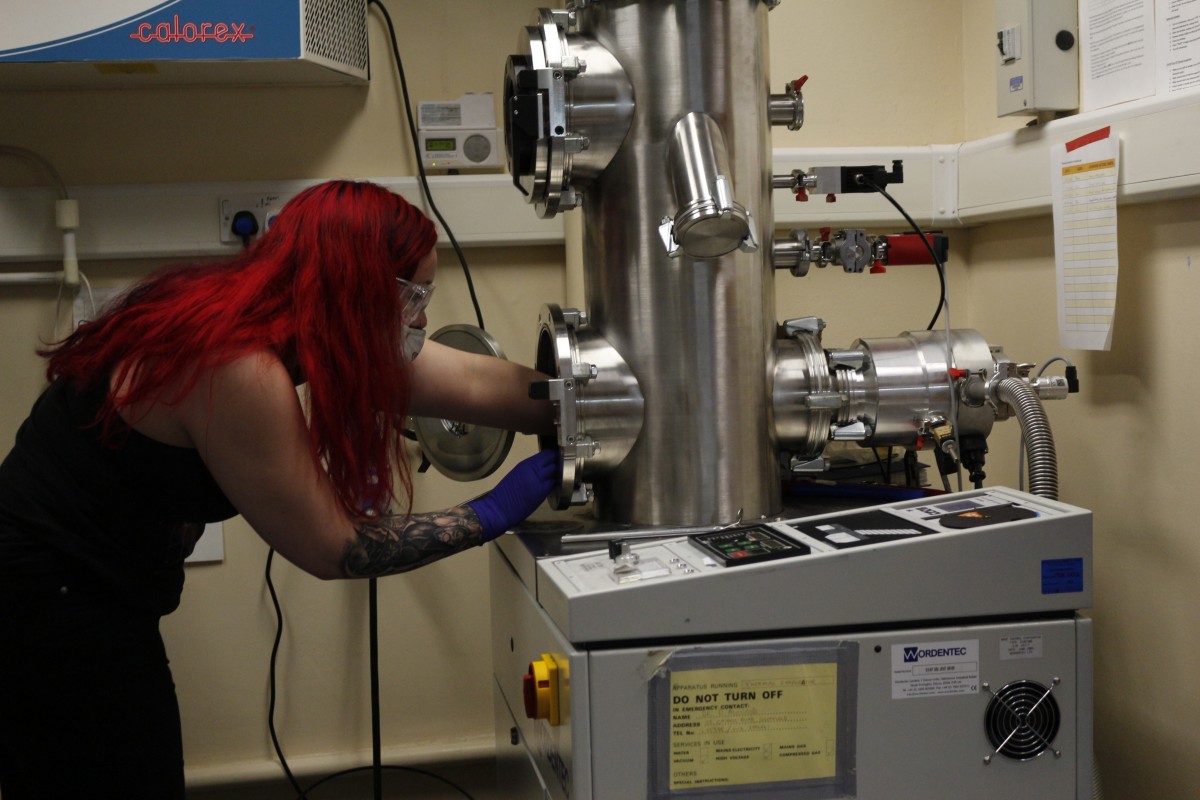

Thin film deposition

Simpler thin film deposition systems include:

- Custom-built three-source thermal evaporator (Wordentec Ltd)

- Three-source sputter deposition system (adapted from a Kurt J Lesker system)

- Single-source sputter deposition system (Nordiko)

- Thermal evaporation for device contacts (Edwards 360 systems, housed in Nanoscience and Technology Building)

Electron beam lithography

Raith Voyager electron beam lithography (EBL) system, as part of the University's EBL Facility.

The system has the following capablities:

- <10nm demonstrated patterning resolution

- <25nm demonstrated overlay and stitching accuracy

- <90 minute patterning time for 1cm2 area (50% coverage, grating pattern)

Device fabrication

We use the Device Lab that is part of the Nanoscience and Technology Building to pattern micro-scale features and prepare electrical contacts to devices.

Facilities include:

- Photolithography

- Resist preparation

- Thermal evaporation

- Wire bonding

Characterisation

We have a range of analytical instruments for characterising the magnetic behaviour of materials. These include systems dedicated to measurement of single structures to those suitable for thin films and bulk samples.

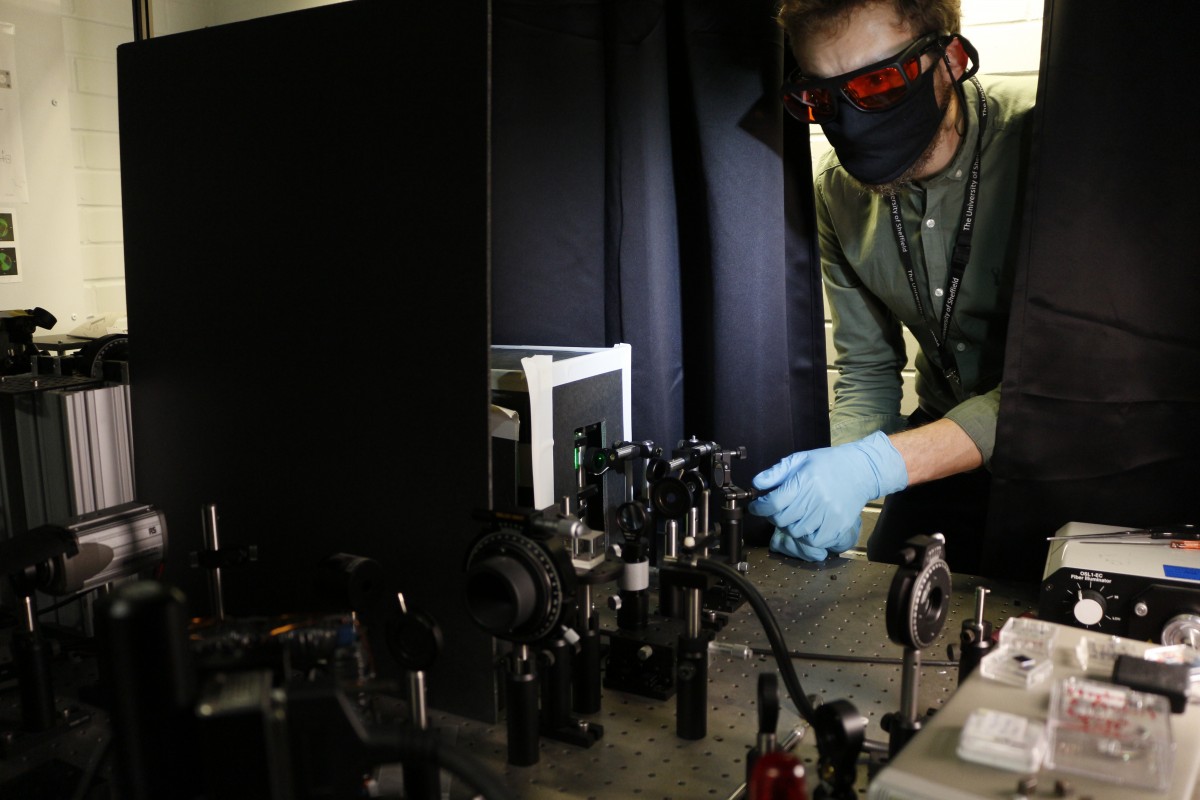

Optical Techniques

We have a range of lab-built 'magneto-optical Kerr effect' (MOKE) systems for studying different sample types:

Focussed MOKE Magnetometry

Capable of single-reversal sensitivity with individual magnetic nanostructures. Spatial resolution of 4-7 microns in a low-noise environment.

Radial MOKE Magnetometry

Uses non-uniformly-polarised light beams to achieve sub-diffraction-limit resolution measurements of thin films and nanostructures.

High-Field MOKE Magnetometry

Measurements on magnetic thin films under fields up to 0.5 T.

Low-Field MOKE Magnetometry

Suitable for analysis of soft magnetic thin films

Scanning MOKE Magnetometry

Integrated MOKE characterisation at a range of sample positions for high-throughput characterisation of multi-component thin film systems.

Non-optical Techniques

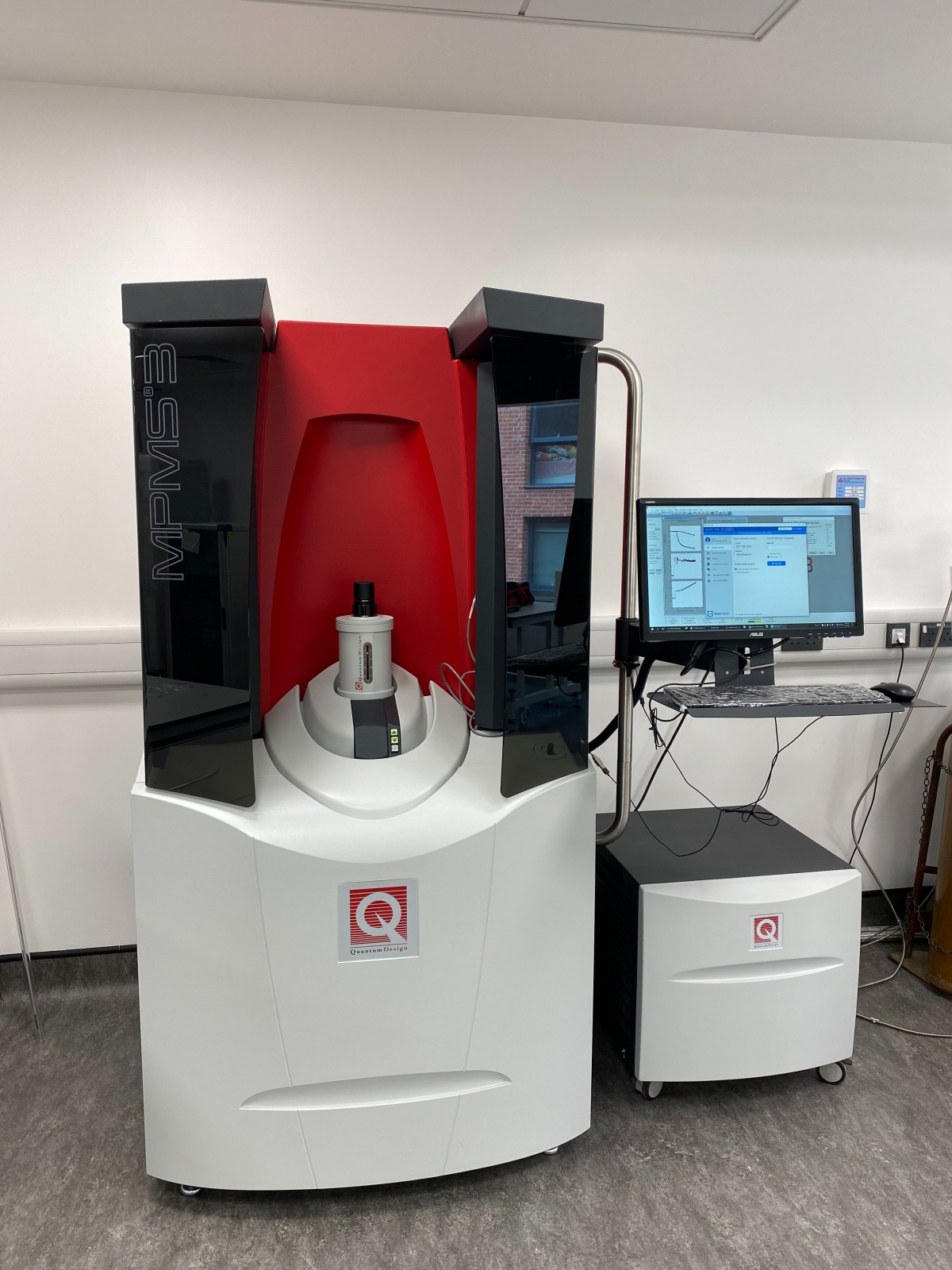

SQUID-VSM

Quantum Design MPMS3 system (part of Henry Royce Institute):

-

Magnetic fields up to 7.0 T

-

Magnetic moment sensitivity: <10-8 emu to > 2 emu

-

Temperature range: 1.8 - 1000 K

-

AC susceptiblity capability

-

Resistance measurement capability

-

Horizontal rotator (multi-axis measurement)

-

Rapid cooling rate and field sweep rate

Transport (Magnetoresistance) Magnetometry

Various MR measurements for magnetic thin films and devices in fields of up to 0.5 T.

Vector Network Analyser (VNA) Ferromagnetic Resonance Magnetometry (FMR)

Vector Network Analyzer – Ferromagnetic Resonance Magnetometry is a non-destructive measurement technique that probes the dynamic behaviour of a magnetic material in the frequency range of MHz to GHz.

The ferromagnetic resonance response that is probed is a collective excitation of the magnetic moments causing the precession around an applied field direction. This precession is in phase across all the moments within a sample, and can be driven by the application of both a magnetic field and a radio-frequency signal. Due to the collective nature of this response, material characteristics can be determined.

The VNA-FMR set-up within our lab allows for multiple measurement types that can be used, Field-Domain (both reflection and transmission), Frequency-Domain (reflection and transmission), and Field Modulated-Domain.

Imaging Techniques

Magnetic Force Microscopy (MFM) (Veeco Dimension 3100)

This is used to perform atomic and magnetic force microscopy (AFM/MFM). A silicon pyramidal tip, coated with magnetic material, is vibrated close (~50 nm) to the surface of a sample and rastered in order to scan an area up to 500 µm x 500 µm. The phase, frequency or amplitude shift generated by the interaction of the tip with the sample surface provides information about the sample. In AFM, this is topological information. In MFM, with a magnetically-coated tip, the image is related to the sample's magnetic domain structure.

Computation

Distributed Computing Resources

MX200 Computing Cluster

This cluster is managed by the Materials Science and Engineering department here at the University of Sheffield.

MX2012 Computing Cluster

This cluster is managed by the Materials Science and Engineering department here at the University of Sheffield.

Iceberg High Performance Computing Cluster

This is a university-wide cluster and is managed by CiCS on behalf of the University of Sheffield. For more information visit: http://shef.ac.uk/wrgrid/iceberg

Micromagnetic Modelling Software

OOMMF

OOMMF (Object-Oriented Micromagnetic Framework) is a CPU-based, open source, finite difference micromagnetic solver. In our group OOMMF is typically used to simulate magnetic domain wall propagation along permalloy nanowires. Jobs are typically run overnight on desktop workstations, however, larger jobs are usually run on one of the MX computing clusters. For more information visit: http://math.nist.gov/oommf

FEMME

FEMME (Finite Element MicroMagnEtics) is a CPU-based, proprietary, finite element micromagnetic solver. FEMME is typically used for simulating fully three-dimensional structures that involve complex geometries and multiple materials such as in granular media or micromagnetic devices. FEMME jobs are exclusively executed on our MX computing clusters. For more information visit: http://suessco.com/en/simulations/solutions/femme-software

mumax3

mumax3 is a GPU-based, open source, finite difference micromagnetic solver and was first used in our group in early 2014. We currently run mumax jobs on two dedicated PCs, with each PC containing two GPUs for a simulation potential of four concurrent jobs. On the right hardware mumax typically executes ~10-20x faster than competing CPU-based simulation software such as OOMMF. For more information visit: http://mumax.github.io

Vampire

Vampire is an open-source CPU-based, atomistic simulation package. Developed at York University, it offers the ability to model complex systems at a natural atomic scale, it can be used to model granular systems, heat-assisted recording and more. Vampire offers a number of methods to solve simulations, similar to micromagnetic solvers orMonte Carlo methods, with the options of output 3D visuals or data logs. Jobs can be run on a workstation, or on the MX cluster. For more information please visit: http://vampire.york.ac.uk